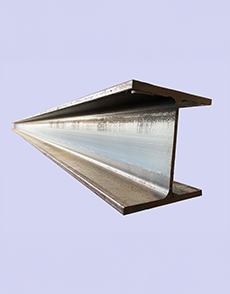

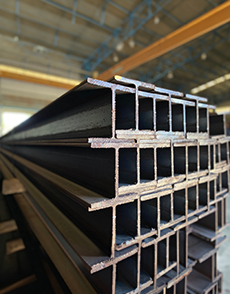

Narrow Parallel Beam

A narrow parallel beam is a type of steel beam recognized by the slim, elongated shape with parallel flanges. Specifically, it is designed to offer high strength and load-bearing capacity alongside sustaining a compact profile, ideal for applications requiring material usage and minimal space occupation. A distinctive characteristic of narrow parallel beams is their capability to evenly spread weight along their entire length, offering excellent structural support and stability. This characteristic is especially beneficial in construction and engineering projects that require strict limitations on space and optimal use of materials.

Get a free quote

Benefits

In the construction sector, slender parallel beams are mainly utilized for forming frameworks for buildings, bridges, and other structures, enabling architects and engineers to create unique and visually appealing designs

- Maintains strength and safety.

- Bears heavy loads and last a long time.

- Perfect for holding up heavy machines and equipment, guaranteeing efficient operations and safety.

Chemical Properties

Carbon Content (%)

≤ 0.25%

Manganese Content (%)

0.50% - 1.50%

Sulphur, Phosphorus Levels (%)

≤ 0.045%

Mechanical Properties

Yield Strength (MPa)

≥ 250

Tensile Strength (MPa)

≥ 410

Elongation (%)

≥ 22%

Other Specifications

Hardness

130 - 170 HB

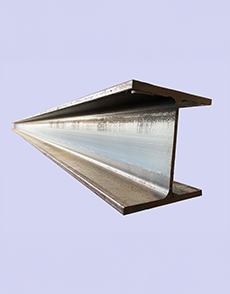

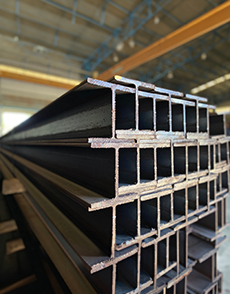

MS Beams

Our MS Beams are made with premium-grade mild steel, designed to provide superior load-capacity and stability available in various sizes and specifications to meet the requirements of the projects. Mild Steel ( MS) beams are beams utilized in construction widely used in constructions and engineering projects like bridges, buildings, boilers, frames of industrial buildings, conveyors, steel structures and so on.

Get a free quote

Benefits

An important benefit of MS Beams is their great weldability and machinability.

- Enabling simple customization and integration into various designs.

- High tensile strength and ability to resist deformation when loaded.

- A dependable option for temporary and permanent structures.

Chemical Properties

Carbon Content (%)

≤ 0.30%

Manganese Content (%)

0.50% - 1.00%

Sulphur, Phosphorus Levels (%)

≤ 0.050%

Mechanical Properties

Yield Strength (MPa)

250-350

Tensile Strength (MPa)

410-560

Elongation (%)

≥ 20%

Other Specifications

Hardness

140 - 190 HB