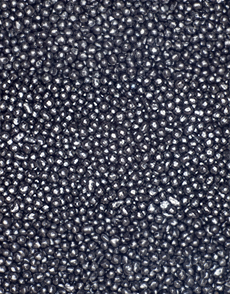

Sponge Iron

Sponge iron, also called as Direct Reduced Iron (DRI), is a significant component when it comes to modern steel manufacturing.Sponge iron allows steel manufacturers to attain higher quality in their end products. We provide different grades to accommodate various furnace types and end-product specifications

Get a free quote

Benefits

Our sponge iron products are designed to meet the top industry requirements, guaranteeing excellent metallurgical characteristics and steady performance in different uses.

- It is a clean and cost-effective alternative.

- Contains high metallic content and minimal impurities.

- Sponge iron is easy to handle and transport.

Our Services Areas

Pellete Sponge

Our Pellet Sponge Iron is made with cutting-edge technology and high-quality materials to ensure exceptional purity and density. Perfect for the steel industry, it offers superb reducibility and consistency, improving the effectiveness and quality of steel manufacturing.

Chemical Properties

Fe Content (%)

66% - 68%

Carbon Content (%)

0.1% - 0.2%

Silica Content (%)

1.5% - 2.5%

Mechanical Properties

Density (kg/m³)

3.0 - 3.5

Porosity (%)

25% - 30%

Other Specifications

Metallic Iron (%)

90% - 94%

Size Range (mm)

9 - 16

Pellete Sponge

Our Pellet Sponge Iron is made with cutting-edge technology and high-quality materials to ensure exceptional purity and density. Perfect for the steel industry, it offers superb reducibility and consistency, improving the effectiveness and quality of steel manufacturing.

Chemical Properties

Fe Content (%)

66% - 68%

Carbon Content (%)

0.1% - 0.2%

Silica Content (%)

2.0% - 3.5%

Mechanical Properties

Density (kg/m³)

2.8 - 3.3

Porosity (%)

25% - 30%

Other Specifications

Metallic Iron (%)

88% - 92%

Size Range (mm)

5 - 20